In the field of instrumentation and measurement, BSPT and BSPP threads are two common thread standards. Although these two standards are similar, they each have their own advantages and are widely used in industrial and construction fields. As a common method of pipe connection, threaded connections play a crucial role. The British Standard Pipe (BSP) thread standard, an important standard in this field, includes two main types: BSPT (British Standard Pipe Taper) and BSPP (British Standard Pipe Parallel). These two thread standards have significant differences in various aspects, such as design features, application areas, and sealing methods. Therefore, a thorough understanding and mastery of these differences are particularly important for engineers when choosing the appropriate connection method.

The BSPT thread presents a conical shape, and its design feature lies in the gradual narrowing of the thread length. Specifically, the diameter of the BSPT thread decreases gradually from the bottom to the top of the nut. This design gives the BSPT the ability to apply greater pressure at the threaded part during connection, thereby enhancing its sealing performance. The conical thread is particularly suitable for applications with extremely strict sealing requirements, such as pipelines for liquid and gas transportation.

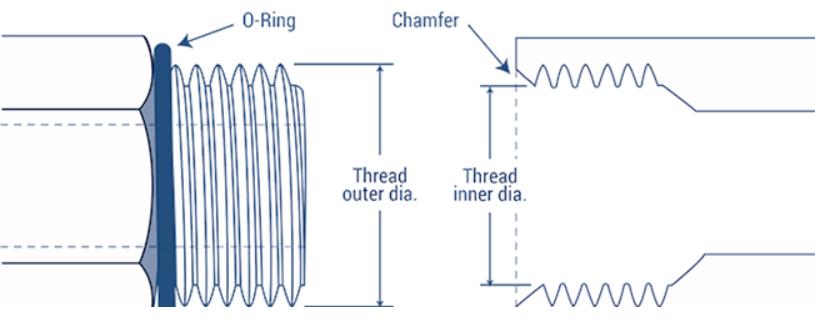

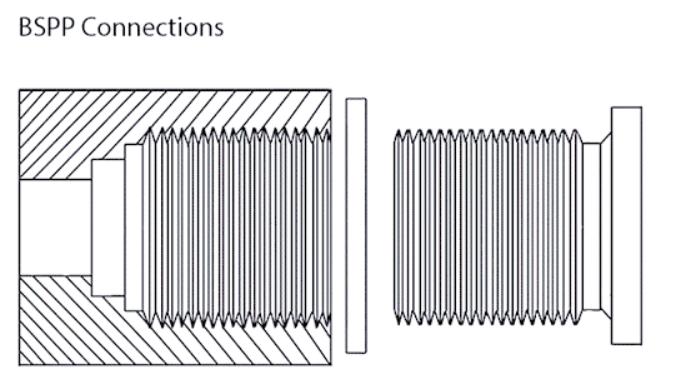

The BSPP thread presents a parallel shape. Its uniqueness lies in the fact that the diameter of the thread remains constant throughout its entire length. Therefore, during the connection process, the BSPP thread does not achieve a sealing effect through the mutual pressing of the threads. Instead, other sealing methods, such as using sealing gaskets or O-rings, are required to achieve good sealing performance.

The BSPT thread performs exceptionally well in high-pressure and sealing-required environments, such as liquid and gas transportation systems. In water pipes, gas pipelines, and high-pressure liquid transportation scenarios, the BSPT thread can provide excellent sealing performance through its self-sealing effect, effectively reducing the risk of leakage and ensuring the safety and stability of the system. While the BSPP thread, due to its parallel shape, is more suitable for low-pressure systems or environments where it needs to work in conjunction with other components. These threaded connections usually achieve sealing through means such as sealing gaskets, and are more suitable for simple connection operations, such as interface connections of instruments and equipment, as well as various applications in non-high-pressure environments.

The connection method of BSPT threads is characterized by self-sealing. As the threads are gradually tightened, their conical design causes the contact area at the connection point to continuously increase, thereby achieving a better sealing effect. This feature makes BSPT threads excellent for liquid and gas transportation, effectively preventing leakage problems.

In contrast, the sealing of BSPP threads relies on the assistance of external sealing materials. When using BSPP for connection, it is usually necessary to equip with sealing gaskets or other sealing components to ensure the tightness of the connection. Although this sealing method may increase the complexity of maintenance in some cases, it also provides greater flexibility and can meet the application requirements of various non-high-pressure environments.

When choosing between BSPT and BSPP, the following key factors should be taken into consideration comprehensively:

Pressure-bearing capacity: For systems operating under high pressure, BSPT threads are recommended.

Sealing performance requirements: For systems requiring high sealing performance, BSPT threads are more suitable; if the sealing requirement is lower and the connection is simple, BSPP threads can meet the needs.

Installation compatibility: Based on the existing connection components and materials, the type of thread that can be compatible should be selected.

In conclusion, BSPT and BSPP, as two different British standard pipe thread standards, each have their unique design features and applicable scenarios. A thorough understanding of the differences between them is crucial for selecting the appropriate connection method, enhancing system safety and reliability. When designing and installing pipeline systems, engineers and technicians should accurately identify and appropriately utilize these two thread standards.

Top 10 Beam Clamp Manufacturers in China – Bulk Wholesaler & Factory Wholesale Price Guide 2026

Top 10 Male Enlarger Manufacturers in China for Explosion-Proof Conduit Fittings

Top 10 Explosion-Proof Conduit Outlet Box Manufacturers And Suppliers in China (2026 Ranking)

High-Performance Blast Hose Coupling for Sandblasting Equipment (2026 Technical Guide)

Top Quick Connect Air Fittings Manufacturers And Suppliers in China (2026 Industry Guide)

content is empty!